When reciprocating compressors make sense in industrial systems

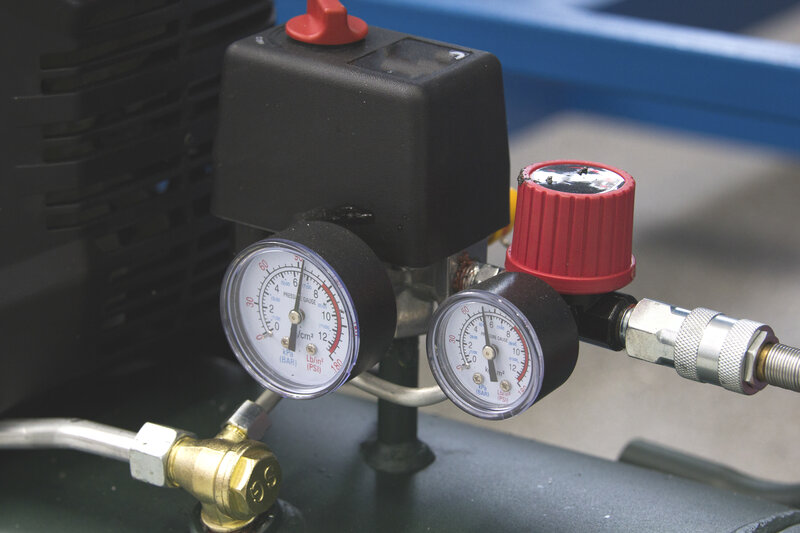

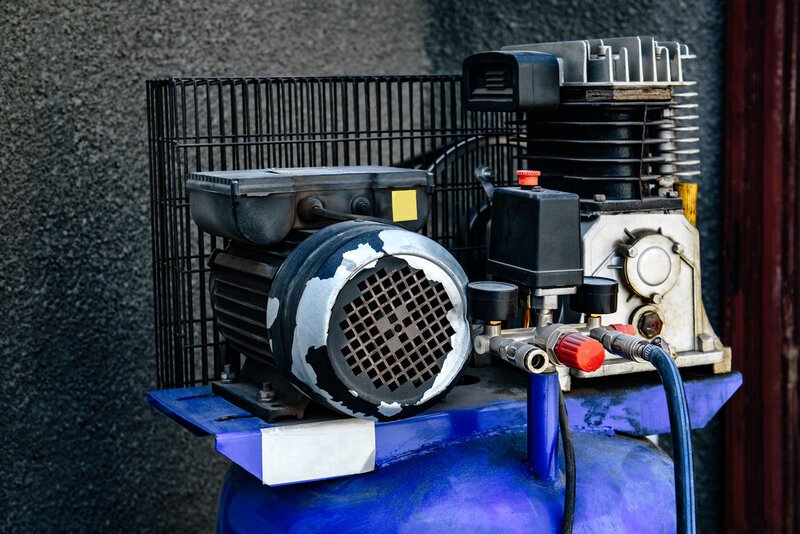

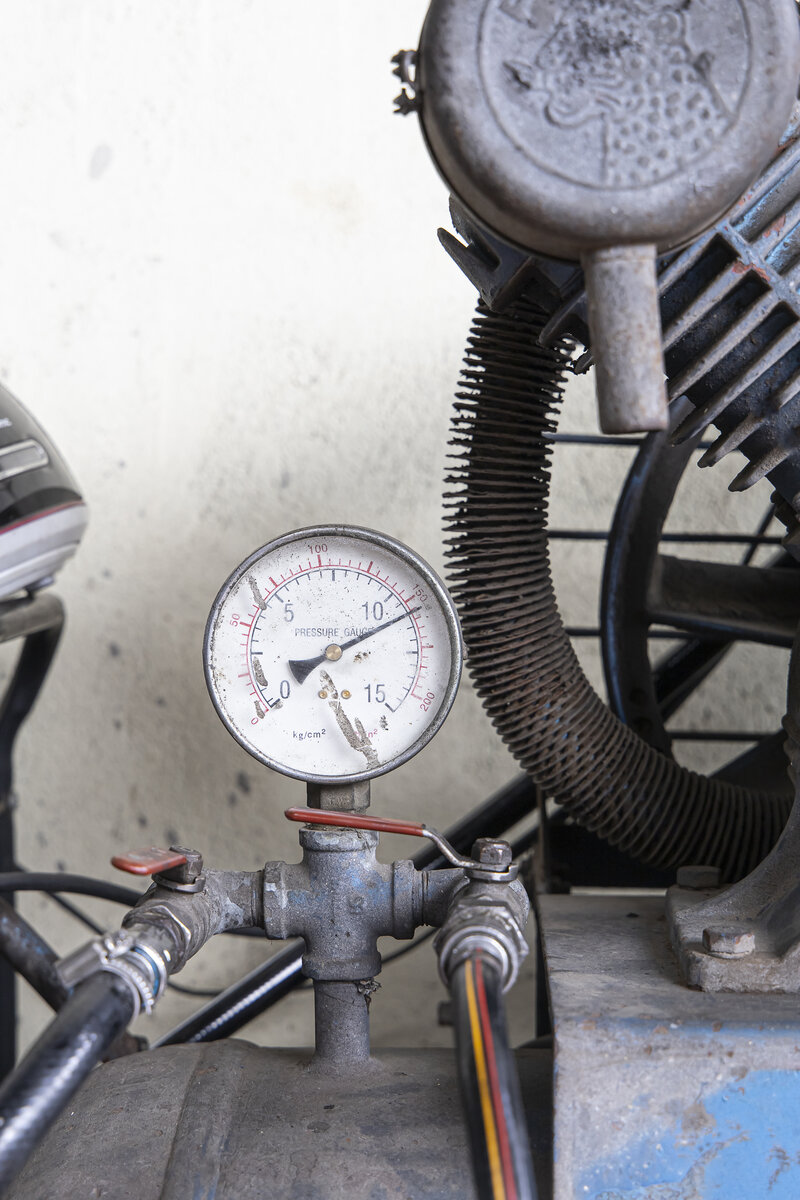

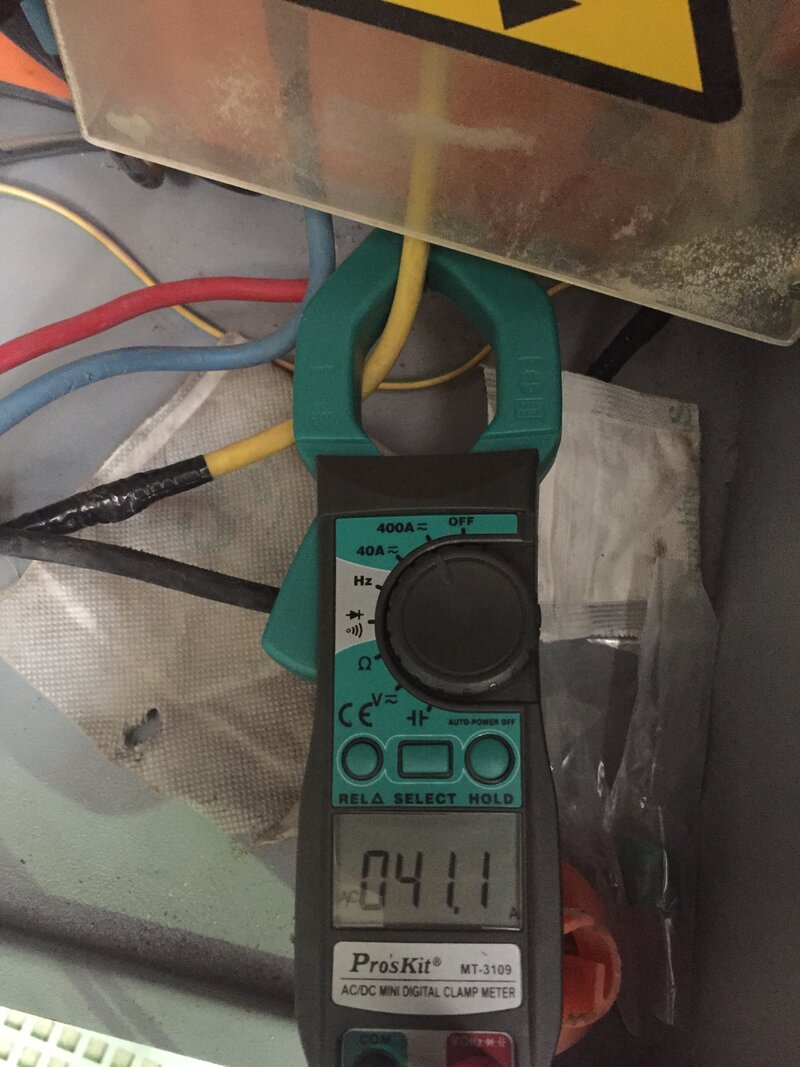

Reciprocating compressors are commonly used for intermittent duty, higher pressure requirements, and smaller air demands. In continuous-duty or high-flow applications, system design and compressor selection become critical to reliability and operating cost.

Learn about system design considerations