Rotary Screw Air Compressor Troubleshooting

Independent troubleshooting for common rotary screw compressor issues — with a focus on fast diagnostics and minimizing unscheduled production downtime.

Start here if you work on rotary screw compressors

Rotary screw compressors are reliable — but when something goes wrong, the root cause isn't always obvious. This page helps you diagnose the most common rotary screw problems quickly, avoid unnecessary part swaps, and reduce downtime using practical field-tested steps.

What Problem Are You Trying To Fix?

Choose the symptom you're seeing. Each page includes causes, diagnostics, and practical fixes you can apply immediately.

Compressor Won't Start

Power, controls, safety circuits, starter faults

View troubleshooting

Runs But Won't Load

Inlet valve, solenoid, control air problems

View troubleshooting

Low Pressure / Can't Reach Setpoint

Leaks, restrictions, valve issues, air-end wear

View troubleshooting

Overheating

Cooling faults, dirty coolers, oil issues

View troubleshooting

Oil in Compressed Air

Separator issues, carryover, oil type problems

View troubleshooting

Water in Air Lines

Drying issues, failed drains, dew point problems

View troubleshooting

Unusual Noise

Bearings, mounts, misalignment, mechanical damage

View troubleshooting

High Energy Use

Control issues, cycling, leaks, system design

View troubleshooting

Pressure Drop

Piping, filters, distribution issues

View troubleshooting

Safety Valve Blows

Overpressure, unloading faults, restrictions

View troubleshooting

Overload Relay Trips

Motor current, binding, electrical faults

View troubleshootingIf you don't see your symptom here, browse the Q&A archive or ask a question below.

Why rotary screw problems happen (most of the time)

Many breakdowns aren't "mystery failures." They come from a small set of root causes — usually tied to heat, air quality, poor drainage, neglected filters, and installation practices. Fix the root cause and you reduce repeat faults.

Heat & cooling problems

Dirty coolers, restricted airflow, high ambient temperature, or cooling fan issues can trigger high-temp trips and accelerated oil breakdown.

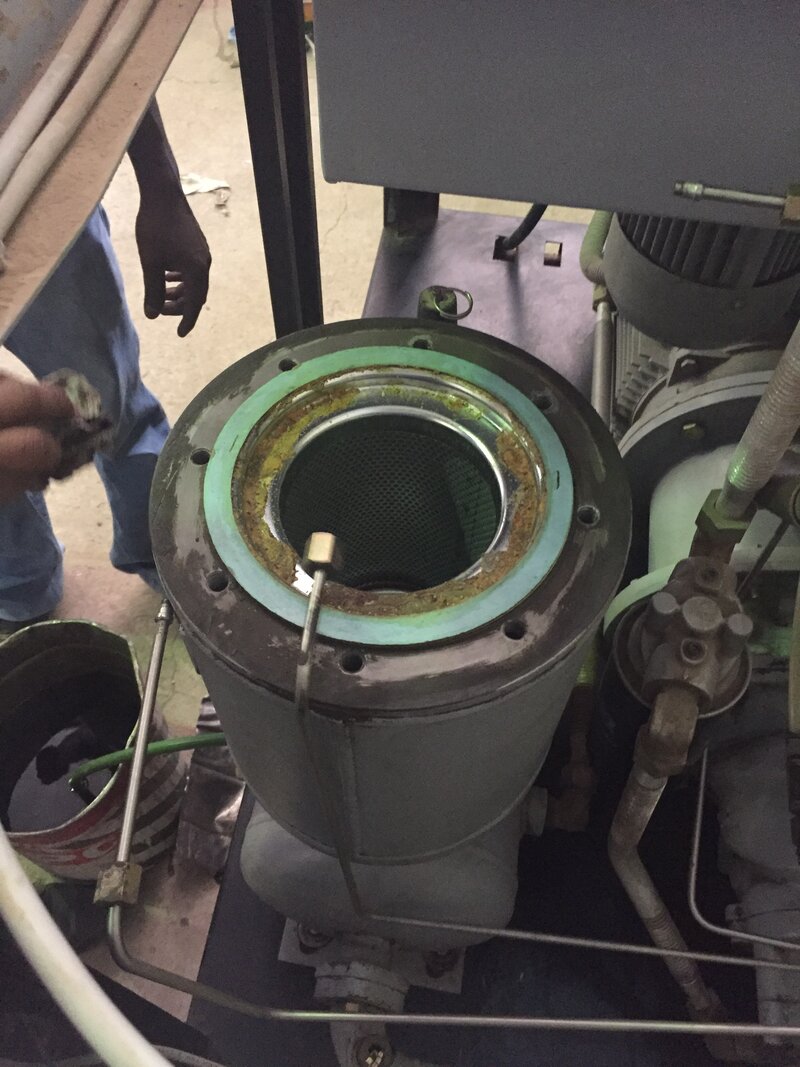

Contamination (dust, oil, water)

Poor intake filtration, wet air, and contaminated oil reduce separator life, foul valves, and increase wear in the air-end over time.

Installation & ventilation

Bad ventilation, undersized piping, and poor condensate management lead to pressure problems, temperature issues, and unstable control behavior.

Maintenance gaps

Neglected filters, incorrect oil type/intervals, and missed inspections cause avoidable shutdowns and expensive failures.

The Complete Guide to Diagnosing and Fixing Rotary Screw Air Compressor Problems

Save time, reduce downtime, and fix issues right the first time — with proven troubleshooting methods used across thousands of service calls.

- Step-by-step diagnostics for common rotary screw failures

- Root cause analysis techniques used by senior technicians

- Practical fixes with parts notes and time estimates

- Methods that work across all major rotary screw brands

- Checklists to help minimize unscheduled production downtime

Still stuck on a rotary screw issue?

If your symptom isn't listed above or you've tried the basics, ask your question in the Q&A section. It's the largest independent archive for industrial compressed air troubleshooting.