Compressed Air System Optimization

Here's something most plant managers don't realize: You're probably wasting 20-40% of the money you spend on compressed air.

Not because you bought the wrong compressor. Not because your equipment is broken. But because of systematic inefficiencies that have accumulated over the years—leaks, excessive pressure, poor control strategies, and wasted heat.

Over 20+ years, I've audited hundreds of compressed air systems. The pattern is always the same: A typical 100 HP compressor costs about $45,000 per year to run. Of that, $9,000-$18,000 is completely wasted on fixable problems.

The good news? Most of these savings have payback periods under a year. Some under 6 months.

Why do air compressors use so much energy?

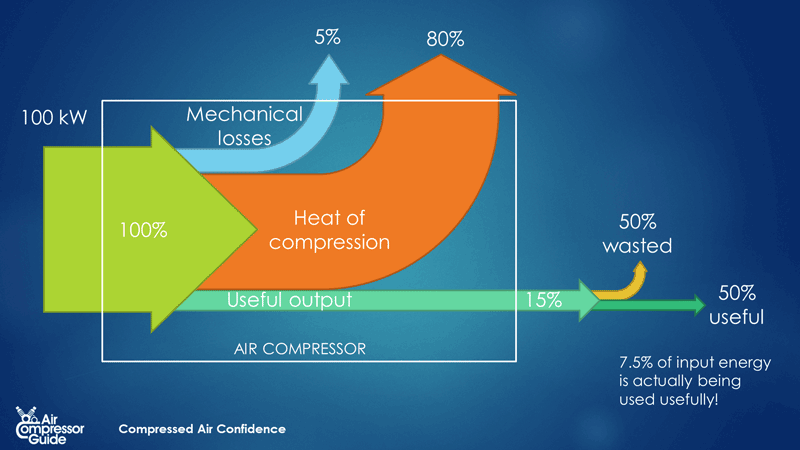

Not many people realize it – but compressors use huge amounts of energy. Compressed air is about 7 to 8 times more expensive than electricity. This is because most of the (electrical) energy input into the compressor is lost during compression. Only 15% of the initial input is available as compressed air "power". And the worst part; of that 15% another 30-to-50% of it is usually wasted (transportation, leaks, etc).

The upside? This gives us HUGE incentives for energy (and cost!) savings - by reducing these wastes, and also in other forms like heat recovery (as you see in the sankey

diagram, there's a lot of opportunity there as well).

Where the Money Is Going (And How to Stop It)

The Big 4 Energy Wasters

Most plants waste 20-40% of compressed air energy through four systematic problems:

Air Leaks - A single 1/4" leak wastes $2,500-$3,500 per year. The typical factory has dozens.

Excessive Pressure - Running 10-20 PSI higher than needed wastes 5-10% energy. Usually done "just to be safe."

Pressure Drop - Undersized piping forces you to over-pressurize, wasting energy throughout the entire system.

Inefficient Control - Old load/unload compressors waste 15-35% of power when unloaded (producing zero air).

Total waste: $18,000-$30,000 per year on a typical 100 HP system. Payback on fixes: 6-18 months.

→ Get the complete breakdown: Common Energy Wasters in Compressed Air Systems

Complete guide to THE BIG 4 with real examples, diagnostic procedures, ROI calculations, and how to fix each one.

Multi-Compressor Control & Sequencing

If you're running 3+ compressors, how you coordinate them can mean $100,000-$300,000 per year in savings.

I've walked into plants with 5-8 compressors running independently, fighting each other. Result: 15-30% more energy than necessary.

Simple fix: Advanced sequencing controller that coordinates all units to minimize total energy consumption.

Real savings examples: $51,000/year, $786,000/year, $468,000/year

Payback: 6-24 months typical

Who needs this: Facilities with 3+ compressors, 200+ total HP, $75,000+ annual energy cost

→ See how it works: Multi-Compressor Control & Sequencing

Control strategies explained, real project examples with actual savings, and implementation guide.

Heat Recovery Systems

70-90% of the electrical energy you put into a compressor comes out as heat.

At small scale (under 50 HP), that heat gets vented. At larger scale (100+ HP, especially 500+ HP), heat recovery becomes a massive opportunity.

Example: 1,000 HP compressor = $200,000-$300,000 per year in recoverable heat (replacing natural gas heating)

Real projects: $450,000/year, $180,000/year, $220,000/year savings. Payback: 1-3 years typical.

Common applications: Process hot water, space heating, process air heating, absorption chilling

When it makes sense: 200+ HP with year-round heat demand

→ Calculate your potential: Heat Recovery Systems & ROI

Heat recovery fundamentals, applications, system design, real project case studies, and ROI calculations.

How to Get Started

DIY System Assessment

Want to identify opportunities yourself?

Most optimization starts with a simple assessment: measure baseline energy, find leaks, check pressure, identify waste.

You can do this yourself with basic tools (pressure gauges, data loggers, leak detector) and a systematic approach.

Typical findings: $15,000-$40,000+ in recoverable savings on a 100 HP system

Time required: 2-4 weeks for complete assessment

→ Step-by-step guide: DIY Compressed Air System Assessment

Complete walkthrough: what to measure, how to measure it, how to calculate savings potential, and how to prioritize improvements.

Professional Energy Audits

For larger or more complex systems, professional audit often pays for itself.

When it makes sense: Systems over 100 HP, multiple compressors, $50,000+ annual energy cost, haven't optimized in 5+ years

What you get: Data logging, leak detection with ultrasonic equipment, system modeling, optimization recommendations with ROI calculations

Typical cost: $5,000-$30,000

Expected findings: $20,000-$200,000+ in annual recoverable savings

ROI: Audit typically pays for itself 2-10× in first year savings

→ Learn more: Professional Compressed Air Energy Audits

When to get one, what to expect, how to choose an auditor, and how to ensure you actually capture the savings.

Tools for Optimization

Compressed Air System Simulator

Compressed Air System Simulator (in development)

Model your multi-compressor system, test different configurations, and calculate ROI for optimization projects before spending money.

Test "what if" scenarios:

- Add VSD compressor vs keep fixed-speed

- Different multi-compressor control strategies

- Heat recovery ROI calculations

- Leak reduction impact

Perfect for: Justifying capital projects to management, comparing equipment options, testing optimization strategies

Status: In development - sign up to be notified at /simulator

Calculators & Quick Tools

Compressed Air Calculators - Quick calculations for:

- Leak cost (what's that 1/4" leak actually costing you?)

- Pressure reduction savings (save by lowering PSI)

- Compressor sizing

- Unit conversions

Training & Implementation

Industrial Compressed Air Systems Course - Complete training covering system optimization, energy audit procedures, leak detection, multi-compressor sequencing, heat recovery implementation, and total cost of ownership analysis.

Q&A Forum - Post details about your system (compressor size/type/quantity, operating hours, energy costs) and I'll help identify opportunities and prioritize improvements.

Industry-Specific Optimization

Different industries have different optimization priorities:

General Manufacturing - Biggest opportunity for energy optimization. Focus on THE BIG 4 wastes.

Energy & Large Industrial - Multi-compressor sequencing and heat recovery are massive opportunities. Systems large enough that 1% = $50,000+/year.

Food, Beverage & Pharmaceutical - Air quality is primary, but heat recovery often worthwhile on oil-free compressors (200+ HP).

Mining & Heavy Mobile - Reliability over efficiency. Limited optimization due to remote/mobile operation, but heat management critical.

Workshops & Small-Scale - Simple optimization: fix leaks, right-size equipment, don't over-pressurize.

Bottom Line

The typical plant wastes 20-40% of compressed air energy through systematic problems with fast payback solutions.

The opportunity: $10,000-$50,000+/year in recoverable savings for most systems

The approach:

- Assess your system (DIY or professional audit)

- Fix THE BIG 4 wastes (leaks, pressure, control, pressure drop)

- Consider heat recovery (if 100+ HP with heat demand)

- Optimize multi-compressor sequencing (if 3+ units)

- Keep optimizing (quarterly leak audits, annual reviews)

Most optimization projects pay for themselves in under 2 years. Many in under 6 months.

You're already paying for the compressed air. Now stop wasting it.

Where to Start

Understand the waste:

→ Common Energy Wasters - THE BIG 4 and how to fix them

Assess your system:

→ DIY System Assessment - Do it yourself guide

→ Professional Energy Audits - When to hire an expert

Advanced optimization:

→ Multi-Compressor Control - For 3+ compressors

→ Heat Recovery Systems - For 100+ HP with heat demand

Get help:

→ Q&A Forum - Post your system details

→ Industrial Systems Course - Complete training