Why Rotary Screw Air Compressors Are Not Recommended For Smaller Applications

When it comes to industrial compressed air systems, rotary screw air compressors play an important role. These compressors fall into the category of positive di...

In-depth articles on air compressor troubleshooting, maintenance, and optimization.

When it comes to industrial compressed air systems, rotary screw air compressors play an important role. These compressors fall into the category of positive di...

Introduction to Air Compressor Noise Issues Air compressors are powerful devices widely used in various industries and homes for numerous applications, from pow...

Compressed air filters are essential components in various industrial and manufacturing processes. They ensure that the air delivered to machinery and tools is...

Industrial screw compressor have an operation state called 'unload running'. In this article we'll discover what this is, why it is necessary and some pro's and...

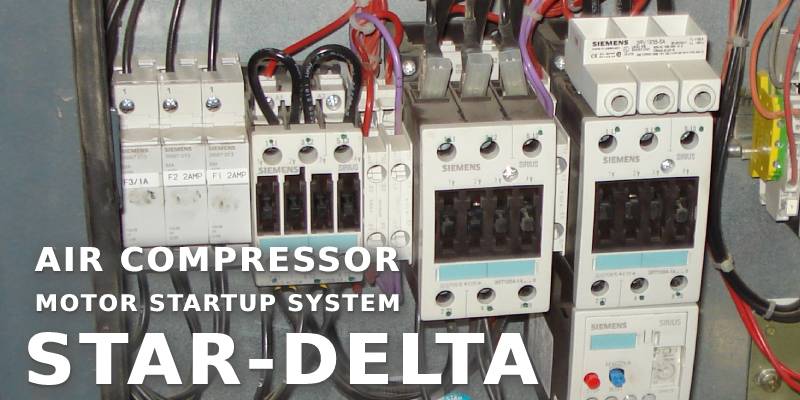

Industrial grade rotary screw air compressors are typically driven by a 3-phase asynchronous electrical motor. These motors range from 5 kW to 1000 kW or more....

Just recently I received a great questions in the Q&A section of my website. "We have a 500 cfm air compressor with loading setpoint of 5.5 bar and un...

Why do compressed air systems need an air receiver anyway? They are bulky, take up a lot of room, costs money.. and they don't do much, or do they? Air receiver...

The cold weather bring a particular set of problems to compressed air systems – and these problems start even before temperatures reach negative values (I’m tal...

I’ve received two similar questions this week, about screw compressors with a very specific problem. I call this an ‘oil vomiting’ air compressor. It’s when oil...

Your compressed air filters need replacement… what do you choose? Those expensive OEM filters or a cheaper copy of them? Nowadays, for almost any brand and mode...

Water in Compressed Air Calculations To continue on the topic of ‘water in your compressed air’ (the other two articles are here and here), let’s examine how we...

Last article talked about water in your compressed air – a problem many of us will face in their compressed air system. So, what is the best way to avoid water...