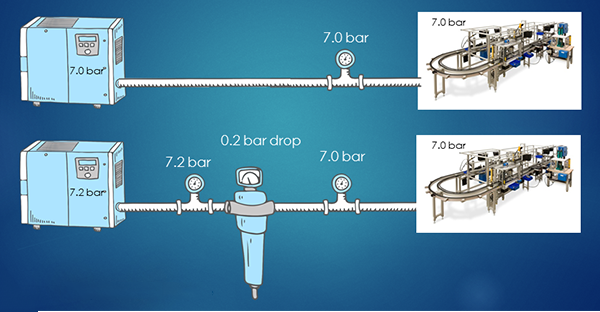

Your compressed air filters need replacement… what do you choose? Those expensive OEM filters or a cheaper copy of them? Nowadays, for almost any brand and model of compressed air filter, there is a cheaper brand or no-name brand available. Those cheaper filter will fit perfectly in the original filter housing. So, is it a good idea to go cheap? Or is buying an original filter money well spend? OEM Filters With OEM filters, I mean filters made by the original manufacturer. So if your compressed air installation was once installed by Ingersoll Rand for example, you most probably have matching Ingersoll Rand compressed air filters for your Ingersoll Rand air compressor. Cheaper Alternatives With cheaper copies I mean all non-OEM filters that have the same size and are designed to fit in the same filter enclosures and are marketed as alternatives to the orriginal. Which one is best for you? So, which one is best for you? Of course it’s not right to just generalize all ‘cheaper alternatives’. There are differences. There are alternative filters that perform equal, or better, than the original filter. The problem is, how do you know? I’ve done a quick search online and found more than a dozen of companies offering their own brands of replacement filters. For some, you can download the datasheet and check the specs. For many, you can’t. I would steer clear of any filter without any datasheet, quality class and/or pressure drop information. If you do want to compare an alternative filter (with datasheet!) to an original filter, keep the following in mind. Air Quality Compare air quality ratings and make sure these are both using same standard. If the quality of the compressed air is important for you, make 100% sure that the replacement filter performs on the same level Running Costs By far the highest cost in a compressed air system is the running cost. Electricity! Did you know that your compressor costs (purchase price) about the same as 1 year of electricity? Over the lifetime of a compressor, electricity amounts for more than 75% of total cost. One of the ways to lower the running costs is to reduce pressure drop. In fact, reducing pressure drop should be your top priority! Looking for a cheaper filter is most of the times the opposite to this!  Pressure drop increases your running costs There are some really good high quality replacement filter manufacturers out there. They make great filters with the same or even lower pressure drop then the original filter. But most filters fail miserably in this category. If your new replacement filter has a pressure drop of 0.4 bar instead of 0.2 bar … it could cost you thousands of dollars per year! Other things to consider There are some other things to consider when choosing between OEM filter or replacement filters. Firstly, look at the rate of saturation, or how fast the filter fills up with dirt and start under-performing. This will both affect the pressure drop and the air quality. Simply said, a datasheet might show an initial pressure drop of 0.1 bar. But the filter might clog up much quicker compared to another filter and reach an higher pressure drop very fast. Also, check the warranty conditions of your equipment. In this article I focused on compressed air filters, so it probably wont impact your air compressors’ warranty. But it might affect the warranty of an air dryer if it is installed downstream of the compressed air filter. Note the cost savings in this article are only true for bigger systems and systems that are used continuously. If your compressor runs just a few hours per week, this is less true. Is it worth it? The way I see it is this: if you’re serious about your compressed air and you use lots of it, your running costs (electricity) will be so high that: 1) you probably wouldn’t mind paying a few hundred dollars for a new filter 2) Any reduction in pressure loss will quickly pay back for the filter. If you’re paying 10.000 dollars a month in electricity, are you going to spend your time worrying about a cheaper compressed air filter, and save maybe $100 a year? Or, are you going to spend your time reducing pressure drops, fixing leaks and making your compressed air system more efficient? And it also means you could spend your time looking for a better performing non-OEM filter! That could save you thousands or tens of thousands a year!

Pressure drop increases your running costs There are some really good high quality replacement filter manufacturers out there. They make great filters with the same or even lower pressure drop then the original filter. But most filters fail miserably in this category. If your new replacement filter has a pressure drop of 0.4 bar instead of 0.2 bar … it could cost you thousands of dollars per year! Other things to consider There are some other things to consider when choosing between OEM filter or replacement filters. Firstly, look at the rate of saturation, or how fast the filter fills up with dirt and start under-performing. This will both affect the pressure drop and the air quality. Simply said, a datasheet might show an initial pressure drop of 0.1 bar. But the filter might clog up much quicker compared to another filter and reach an higher pressure drop very fast. Also, check the warranty conditions of your equipment. In this article I focused on compressed air filters, so it probably wont impact your air compressors’ warranty. But it might affect the warranty of an air dryer if it is installed downstream of the compressed air filter. Note the cost savings in this article are only true for bigger systems and systems that are used continuously. If your compressor runs just a few hours per week, this is less true. Is it worth it? The way I see it is this: if you’re serious about your compressed air and you use lots of it, your running costs (electricity) will be so high that: 1) you probably wouldn’t mind paying a few hundred dollars for a new filter 2) Any reduction in pressure loss will quickly pay back for the filter. If you’re paying 10.000 dollars a month in electricity, are you going to spend your time worrying about a cheaper compressed air filter, and save maybe $100 a year? Or, are you going to spend your time reducing pressure drops, fixing leaks and making your compressed air system more efficient? And it also means you could spend your time looking for a better performing non-OEM filter! That could save you thousands or tens of thousands a year!

Comments

No comments yet…

Log in or create an account to make a comment...