The scroll compressor is another popular type of compressor. It is commonly used in fridges and freezers to pump around the freon. But it can also be used to compress air in you workshop or factory.

How does it work?

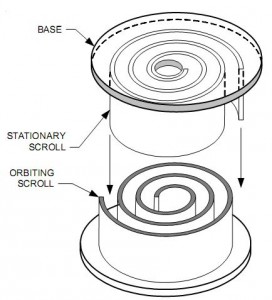

The compressor exists of two spiral elements. One moves in eccentric circles and the other one is stationary. This compressor is a wonderful invention, since it has only 1 moving part.

Working principle of scroll compressor

Working principle of scroll compressor

What happens?

Air gets trapped between the two spirals at the suction side and get transported to the center of the spiral. This way the air is compressed. It takes about 2.5 turns for the air to reach the center exhaust pipe.

The big advantage of this type of compressor is the quiet operation and the oil-free air it produces.Since there are so little moving part and there is no oil, maintenance is very easy.

Actually, it's just a matter of changing the air intake filters once in a while.

Of course nothing is for free in this world: scroll-compressors are a lot more expensive than reciprocating compressors of the same capacity.

Scroll element with parts cut-out to see the inner workings. Photo: Atlas Copco

Scroll element with parts cut-out to see the inner workings. Photo: Atlas Copco

When do you need a scroll compressor?

Do you need a relatively small amount of compressed air? And do you need a quiet compressor? Then the scroll compressor is for you!

This type of compressor is most commonly seen where a small amount of oil-free air is needed.

For example is small specialized workshops, drinking water treatment facilities, and other places where for example loud noise is an issue.

Pros and Cons

Pros:

- Very quiet. Really very quiet!

- Compact. It is very small

- Simple design, not so many parts

- Low maintenance (hardly any)

- Oil-free design

Cons:

- Low capacity (flow, liters/minute or cfpm).

- Relatively expensive

- When the compressor-element fails, there's a very big chance you just have to buy a whole new element.

- The compressed air gets very hot! Much hotter than compared to other types of compressors

Buying a scroll compressor

When buying a this type of compressor, make sure the capacity is enough for your needs.

Nowadays, there are also units with two or four compressor elements in one housing.

Is your equipment sensitive for water? Then you will also need a compressed air dryer. The dryer can often also be installed inside the same unit.

4 compressor elements in one unit. Photo: Atlas Copco

4 compressor elements in one unit. Photo: Atlas Copco

Single compressor element on receiver. Photo: Atlas Copco

Single compressor element on receiver. Photo: Atlas Copco