Save money and troubles by learning how to set your air compressor pressure switch the right way!

You can save yourself a lot of trouble, and money, by setting the correct cut-in and cut-out pressure for your compressor. Learn how to set the pressure switch yourself!

First I will teach you what the correct pressure settings are for your compressor. Than I will show you how to set these pressures on your pressure switch.

The right pressure

Both for small (piston) compressors and for large industrial rotary screw compressors, the pressure setting is the most basic and most important setting of the compressor.

On smaller compressor, the pressure is set up on the pressure switch. On large compressors, it's done on the central compressor controller, but the idea is the same.

Less is more

When deciding what the best pressure is for you and your compressor, always remember to set the pressure as low as possible for your application.

I know most compressor are advertised as 7 bar (125 psi) compressor, and are set at the pressure when you buy them. But if you only need 5 or 6 bar, it's better to lower the pressure.

Every increase in pressure will require more energy. Simple as that. If you own a large compressor ( say 30 kW or bigger), you can save hundreds or thousands of dollars per year in energy costs by lowering the pressure setpoint.

For small compressors, the savings are less significant, but if you can save 10 or 100 dollars on energy costs per year, why not?

Cut-in and cut-out pressure

A compressors always has two pressure set-points: the cut-in and the cut-out setpoint.

These are simply the two pressures at which the compressor starts and stops. The compressor will stop when it reaches the cut-out pressure and will start again when the pressure drops back to the cut-in pressure.

So, the cut-in pressure is always lower than the cut-out pressure. We call the difference between cut-in and cut-out pressure the pressure band or the pressure differential.

A rule of thumb is that the pressure differential of at least 1 bar (14 psi).

If the difference between the cut-in pressure and the cut-out pressure is set too small, the compressor will quickly start and stop repeatedly.

This will burn the compressor motor, will cause extra wear on the compressor components and will damage the pressure switch.

To give an example... Say you need an absolute minimum of 6 bar air in your compressed air installation, if the pressure drops lower, your machines start to malfunction.

You set the minimum pressure on the pressure switch at 6 bar (or 6.1 to be sure) and you set the maximum pressure at 7.1 bar.

Now you always have an high enough pressure in your compressed air system, and you made sure that the compressor stays healthy by not having it start and stop all the time.

Cut-in pressure is 6.1 bar. Pressure differential is 1 bar. This makes the cut-out pressure 7.1 bar.

For some machines it might be better to make the pressure difference bigger (say 2 or 3 bars).

This is better for machines that only run for a very short time.

When you increase the pressure band, the compressor will run longer and has more time to heat up to remove any water or moisture inside the compressor (the number one enemy of compressors!).

Setting the pressure switch

Depending on the make and model of pressure switch, one can adjust only the pressure setting, with a fixed differential, or one can adjust both the pressure setting and the differential.

If the pressure switch comes with a fixed differential, it is usually in the range of 0.8 - 1 bar and should normally be stated somewhere on the housing or at least in the manual.

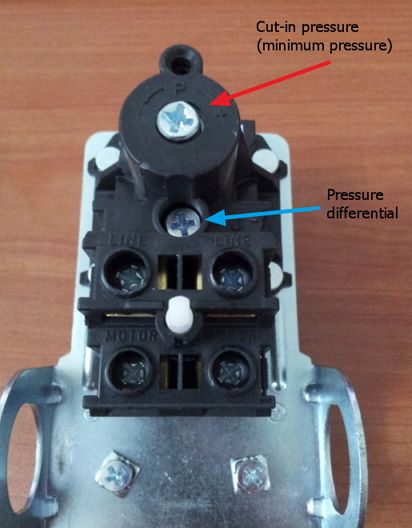

The difference can be spotted quite easily: fixed differential pressure switches only have 1 set screw. Pressure switches with an adjustable differential have a smaller second set-screw.

Setting the pressure switch seems straightforward enough. Just set the cut-in and cut-out pressures, right. Well, from personal experience I can say that it can sometimes be quite frustrating.. especially when you turn the settings too much and loose track of 'where you are'.

I always tend to think think that the pressure switch sets the upper pressure limit with the main adjust screw. That is, I think, what makes it sometimes so frustrating to setup such a 'simple' device...

On most (but not all...) pressure switches, the big set-screw is to set the cut-in pressure. In other words.. to set the lowest pressure. The pressure where the compressor starts-up. Thinking about it, this makes sense, as this is the most important thing for your machine to operate properly (they will operate properly on a higher pressure, but not on a lower pressure).

The smaller screw, the differential setting, then sets the maximum pressure, the cut-out pressure, relative to the cut-in pressure.

So when you change the cut-in pressure (big screw), the cut-out pressure will also change, as it depends on and is on a fixed value away from, the cut-in pressure.

That's what makes it sometimes so frustrating to set the pressure correctly.

Example of set-screws for cut-in and differential pressure.

(This is a Condor MDR 11/11 pressure switch, which are very common)

Step-by-step procedure:

Since the cut-out pressure is defined as the cut-in pressure + the pressure differential, it's best to first set the cut-in pressure.

Setting the cut-in pressure.

- Starting from an empty tank. Start the compressor and let it run until it reaches the cut-out pressure.

- Open a drain to slowly let some air escape. Watch how the pressure slowly comes down.

- Wait until the compressor starts. Write down the pressure. This is the cut-in pressure.

- Adjust the cut-in pressure with the big set screw. Turn clockwise to increase the cut-in pressure.

- Close the drain valve. The compressor will run until the cut-out pressure is reached.

Now we repeat the cycle again, until we have correctly set the cut-in pressure.

- Open a drain valve to slowly let the compressed air escape and wait until the compressor starts.

- Note the pressure at which it starts (the cut-in pressure). Adjust when necessary.

After a few cycles you should have successfully set the cut-in pressure. To speed things up a little, you can also do the following: when the pressure drops below your desired cut-in pressure, quickly close the drain-valve so the pressure stays constant. Now adjust the set-screw (the big one), clock-wise (increase cut-in pressure) until the compressor starts. Depending on how far the actual pressure is below your desired cut-in pressure, turn the screw a little further (quarter-turn or less). Now the cut-in pressure should already be more-or-less OK.

Setting the cut-out pressure

The procedure is somewhat the same as for the cut-in pressure. Now only touch the set-screw for the differential pressure. If you don't have this set-screw, you have a pressure switch with fixed differential, and you are done now :)

- Note the pressure at which the machine stopped last time you let it run.

- Adjust the differential pressure accordingly. Turn clockwise to increase (if you want a higher maximum pressure) or count-clockwise to decrease (if you want a lower maximum pressure.

- Open the drain valve and wait until the pressure drops low enough to start the compressor. Close the drain valve.

- Wait for the compressor to stop. Check the cut-out pressure.

- Repeat.

Reminder

Set the cut-in pressure first. Set the cut-out pressure second.

You have now successfully set the pressure switch.

The procedure can be different depending on your air

compressor pressure switch type. Some pressure switches can only be adjusted when under pressure. Don't turn any of the screws when there is zero pressure in the tank, or when your just get your new pressure switch out of the box. Always check the manual, just to be sure.

Most pressure switches are factory-set at a cut-in pressure of 6 bar with a pressure differential of 1 bar (which makes the cut-out pressure 7 bar).

I have made a basic overview of different models and types of pressure switches. Check out that page if you're interested. And when you're looking to buy a pressure switch, check out my buying a pressure switch page.