Air Compressor Guide: Everything you need to know about air compressors

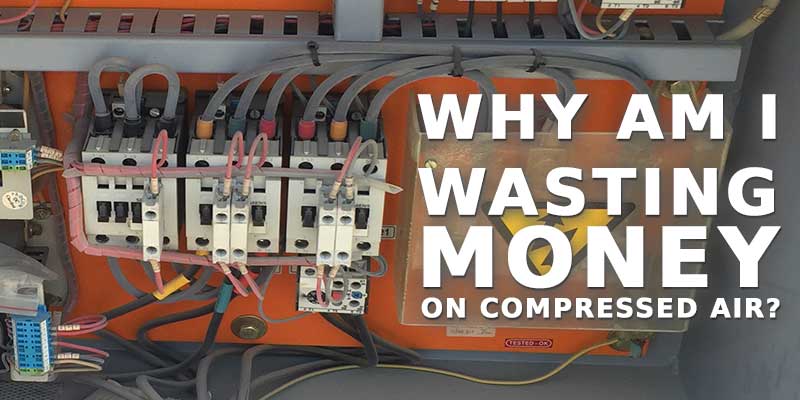

Improve your compressed air system, troubleshoot your air compressor, and stop throwing money away. That's what air-compressor-guide.com is about.

Looking for advice on the good operation of your air compressors and compressed air equipment? You've come to the right place.

Welcome to Air Compressor Guide!

Newsletter

I help compressor owners (and anybody working with compressed air systems) optimize their compressed air system, in order to increase production uptime and lower maintenance and running costs

Signup to my newsletter and I will keep you updated. Unsubscribe at any time.

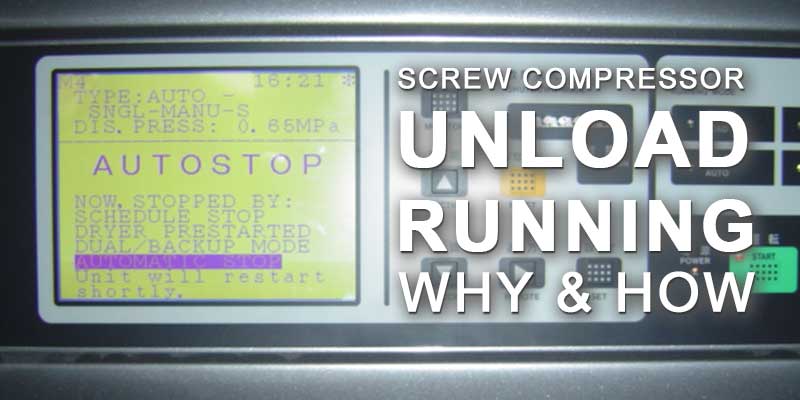

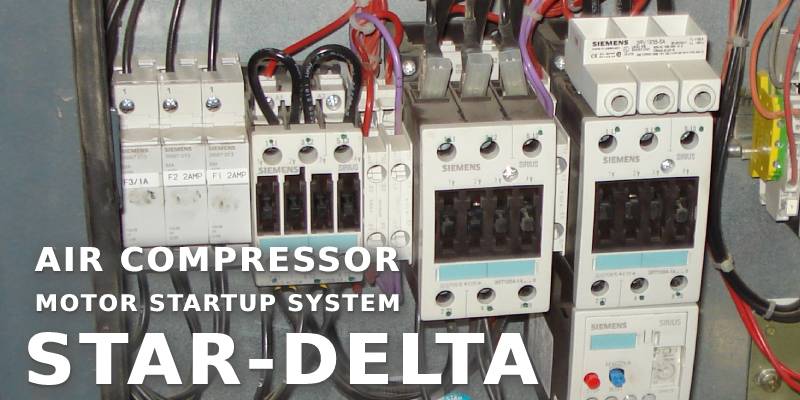

Latest Articles

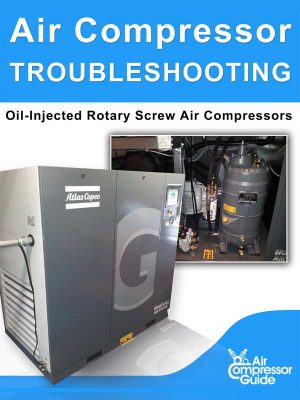

Courses & Guides

Air Compressor Troubleshooting

Even the best compressors fail sometimes. Is your air compressor acting up? Check out on of these pages to het started:

- Air Compressor Troubleshooting - Introduction to air compressor troubleshooting.

- Questions and Answers - Many troubleshooting questions there. Can't find the answer? Ask your own question.

Got a rotary screw compressor amd want to fix problems quickly? Get my Air Compressor Troubleshooting Guide!