Free Air Delivery (FAD) is an important metric in the world of air compressors. It measures the actual amount of compressed air produced by a compressor under specific conditions. Understanding FAD is important for selecting the right air compressor and ensuring efficient operation of compressed air systems.

By normalizing the output of an air compressor to standard conditions, FAD allows us to compared air compressors 'apples to apples'.

What is Free Air Delivery

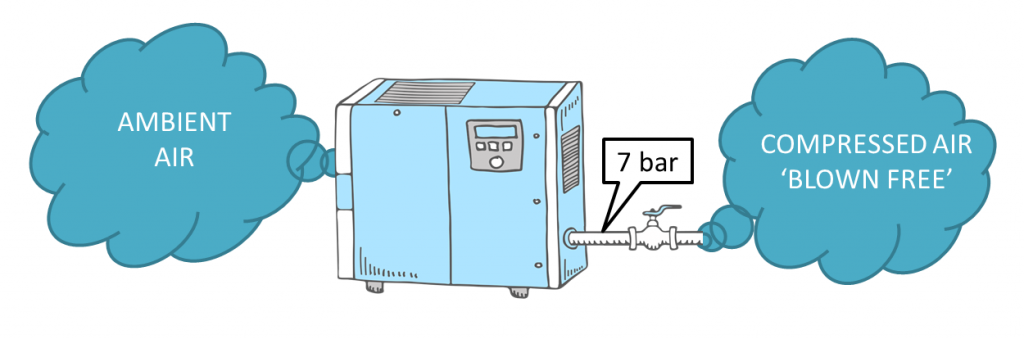

FAD refers to the volume of air drawn into the compressor at atmospheric conditions and delivered at a specific pressure.

FAD = The flow at the compressor outlet calculated back to inlet conditions.

Unlike other airflow measurements, which might include air compressed and stored under pressure, FAD provides a more realistic and practical indication of a compressor's performance.

To understand this, just think of a compressor that compressed air at a certain rate. We let the compressed air blow-free to make it expand back to ambient conditions. And THAT is what we 'measure' when we talk about FAD.

As you see, the air 'blown free' is the same amount of air as the air that the compressor takes in.

To make a fair comparison, we often do this with standardized inlet conditions and measurement method, as described in ISO 1217.

Another way of expressing this is nl/s (normal liter per second) or SCFM (standard cubic feet per minute). The only difference are the reference conditions.

Why use FAD?

FAD in mainly used when determining Compressor Efficiency: It helps in assessing how effectively a compressor converts input (ambient air) into output (compressed air). And it's used for choosing the right compressor: Understanding the FAD is essential for selecting a compressor that meets the specific air demand of your tools or processes.