Reach the lowest possible dew-point (the dryest compressed air), by investing in a desiccant compressed air dryer and remove all the water from your compressed air.

A desiccant compressed air dryer uses a special material, called desiccant to dry the compressed air.

This desiccant is made of a material that really 'likes' water, the water sticks to the surface of the desiccant.

Every once in a while, the desiccant needs to be dried, or 'regenerated', to remove the water again.

Desiccant

To have the largest possible surface, the desiccant is used in the form of thousands of small beads. Types of desiccant that are often used are silica gel and activated alumina.

Activated Alumina. Photo: Atlas Copco

Activated Alumina. Photo: Atlas Copco

Silica Gel. Photo: Atlas Copco

Silica Gel. Photo: Atlas Copco

How a desiccant compressed air dryer works

A desiccant dryer usually has two identical towers, filled with desiccant. One tower is used to dry the compressed air, while the other tower is regenerated.

Every once in a while (controlled by a central control unit) the dryer switches towers. The compressed air is now dried by the second tower, while the first tower, filled with wet, saturated desiccant is dried.

Very simple!

On most dryers, there is a small sight-glass. Behind the glass you can see small beads. This is not the drying-desiccant, but an indicator. It will change color when the air the is too wet. Check it every once in a while to make sure that your dryer is

working properly.

Big desiccant compressed air dryer.

Big desiccant compressed air dryer.

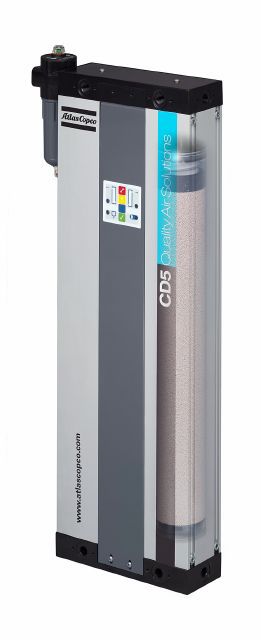

Small desiccant dryer. Photo: Atlas Copco

Small desiccant dryer. Photo: Atlas Copco

Regeneration or drying of the desiccant

When the desiccant has done its job for some time, it has absorbed all the water from the compressed air and is saturated with water. It cannot hold any more water. In order to re-use the desiccant, we need to get rid of all that water. This is called regeneration.

The regeneration process is done in one of the two towers of the air dryer, the one that is not operational. There are two ways the desiccant can be regenerated: by hot air or by dried compressed air.

With the hot air method, a separate system consisting of a fan with an electric heater is used to blow hot air through the desiccant to dry it. This is just normal air drawn from the compressor room.

Dryer which uses heat from the oil-free compressor for regeneration. Photo: Atlas Copco

Dryer which uses heat from the oil-free compressor for regeneration. Photo: Atlas Copco

There are also special dryers available for use with oil-free screw compressors that used the heat of the compressor to regenerate the desiccant (and thus saving energy and money). This type of dryer consists of 1 rotating drum. 1 quarter is being regenerated, while the rest is drying the compressed air.

A third method of drying the desiccant, is with dry compressed air. This is often used in the smaller dryers and is also not suitable for big dryers.

With this method, part of the compressed air that has just been dried is used to regenerate the desiccant. This means that less compressed air is available for your tools and machinery.

Hidden costs

When buying a desiccant compressed air dryer, keep in mind that there are more costs involved than just the purchase price.

Here is a list of things to consider when buying your desiccant compressed air dryer:

- Pressure drop. The dryer will create an extra pressure drop. If the pressure drop over your dryer is for example 0.3 bar, and you need 6 bars to operate your tools, it means you need to set your compressor at 6.3 bars. This extra bit of pressure

requires more energy (and money!) to produce. The bigger your compressor, the higher the extra costs. - Regeneration costs: if you buy a hot-air regeneration-type dryer, consider the electricity costs used to heat the regeneration-air. If buying a compressed-air regeneration-type dryer, consider the air lost in the process. A dryer of this type will consume 15 to 20% of your (expensive) dried air!

- Desiccant use: even though the desiccant is regenerated, it will ‘wear down’ over time. It has to be replaced after a few years

(check the manual).

Installation

There are a few key things to keep in mind when installing your desiccant compressed air dryer. I have seen so many mistakes with this over the years and it's so easy to do it right and save money in the long run!

Pre-filters: always make sure that the air that enters the dryer is clean and free of oil and water drops. Use a moisture trap, a water-filer and an oil filter to clean up the air before the dryer.

Why a condensate trap and water filter? Any liquid water in the compressed air will quickly saturate all the desiccant, making it unable to do its job properly. Result? Your dryer will not be able to get the desired dew-point. Wet air will pass through your dryer.

Why an oil filter? There will always be some oil from your compressor in the compressed air (this is called 'oil carry-over'), unless you have an oil-free compressor of course.

If this oil gets to the desiccant it will stick to the surface of it. Result: your desiccant can't do its job anymore, since it's covered in oil.

Wet air will pass through your dryer. Also, you can probably throw the desiccant away and buy new one, which can be quite expensive.

After-filter: It is advisable to install a dust filter after the desiccant compressed air dryer.

The desiccant will always wear down a bit. This means desiccant-dust will exit the dryer together with the compressed air. Use a dust-filter to remove the desiccant dust to protect your equipment.

Outlet filter with dew-point sensor on this desiccant compressed air dryer. Photo: Atlas Copco

Outlet filter with dew-point sensor on this desiccant compressed air dryer. Photo: Atlas Copco