Learn how a compressor pressure switch works on the inside

To give you a better understanding of pressure switches in general, I will explain on this page how they work.

Pressure

Pressure switches are pressure actuated electrical switches.

Which simply means, that there is an electrical switch, which is forced open or closed by air pressure.

The air pressure at the inlet port acts on a flexible membrane. The pressure in transformed into a force.

How much force depends on two things: the area (square mm's) of the membrane and the pressure (bar) of the compressed air. Since the area is constant, the force generated is directly proportional to the air pressure.

The other side of the membrane is connected to a spring and a lever that acts on the electrical switch. As long as the downward force of the spring is higher than the upward force of the compressed air, the membrane (and lever) stay down.

But when the pressure rises, there comes a point where the upward force of the compressed air is higher than the downward force of the spring.

The membrane (and lever) will move upward at this point. When the membrane moves upward, so does the lever. The lever in turn opens the electrical contacts and the compressor stops.

Now this isn't a direct connection, but there is an ingenious mechanism inside, that makes the switch flip-over at once, at a certain pressure, and not slowly slowly ("snap-action"). This mechanism is also connected to the second set-screw which sets the differential pressure. For the inner workings of the pressure switch, this simply means that the switch closes again at a lower pressure than the pressure where the switch closes (built-in hysteresis).

I will try to explain it with the pressure switch I have here on my desk. I will simulate the air pressure with a screwdriver (instead of the compressed air pushing up, it's me with the screwdriver pushing up :).

This is not recommended when you still want to use your pressure switch, as it will damage the membrane. I bought this pressure switch just for the purpose of illustration, and have no intention of using it on an air compressor, so here it goes...

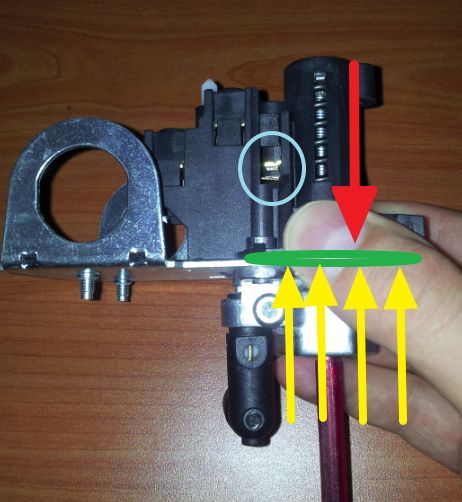

Pressure switch with low air pressure

Pressure switch inner workings at low pressure: the big spring is forcing the membrane (green circle) downwards (red arrow), while the air pressure tries to push it upwards (yellow arrows).

The spring 'wins' and the membrane stays down. The electrical contacts are closed (blue circle)

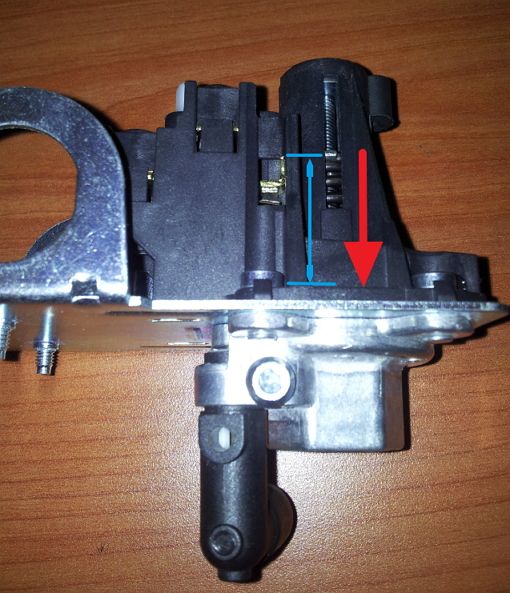

Pressure switch with high air pressure

Pressure switch inner workings at high pressure: the big spring is forcing the membrane (green circle) downwards (red arrow), while the air pressure tries to push it upwards (yellow arrows).

Now the pressure is high enough and the membrane moves upwards. The electrical contacts open (blue circle) and the compressor stops.

Setting the pressure.

To be able to change the pressure setting, the downward force of the big spring can be adjusted (red arrow in above pictures).

The adjustment is done by compressing the spring using a long screw. When you turn the screw clockwise, the spring is compressed more. It will now generate a larger downward force on the membrane, so we need an higer air pressure to overcome this force. In other words: we raised the pressure setting.

When you turn the screw counter-clockwise, the spring becomes less compressed. It will now be easier for the compressed air to push against the spring. In other words: the pressure setting is lowered.

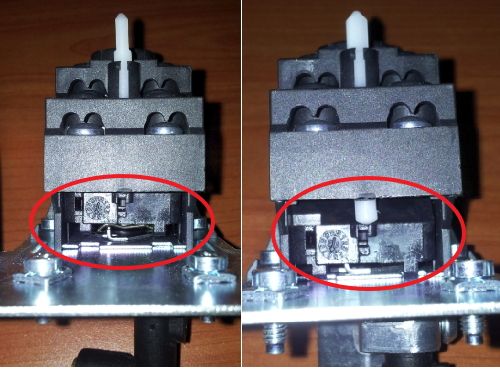

The main spring is almost not compressed. The pressure switch is set at a very low pressure.

The spring is highly compressed now. The pressure switch is set at an high pressure.

The spring is highly compressed now. The pressure switch is set at an high pressure.

The off/on/auto switch

Some pressure switches have a switch or push button for on/off control. On some switches it says "ON / OFF", but the words "AUTO / OFF" would be more correct.

In the AUTO ('ON') position, the pressure switch works as expected. It opens and closed automatically according to the pressure. In the OFF position, the pressure settings are overruled and the electrical contacts are always open. The compressor is stopped.

(an ON postion wouldn't make much sense, as this would make the compressor run indefinately, which of course would result in a way too high pressure).

How does it work? The on/off buttons or switch are connected to a plastic pin. When the pressure switch is set "OFF", the pin pushes down on a plastic block. The plastic block in turn opens the electrical contacts. The compressor will stop and stay stopted.

Auto / off switch action. The white pin pushes down on the black plastic block (red circle).

The black plastic block forces the electrical contacts open and the compressor stops.

If you want more information on setting the correct pressures, check out our air compressor pressure switch settings page.

I have also made a basic overview of different models and types of pressure switches.

And when you're looking to buy a pressure switch, check out my buying a pressure switch page.